お知らせ

News お知らせ

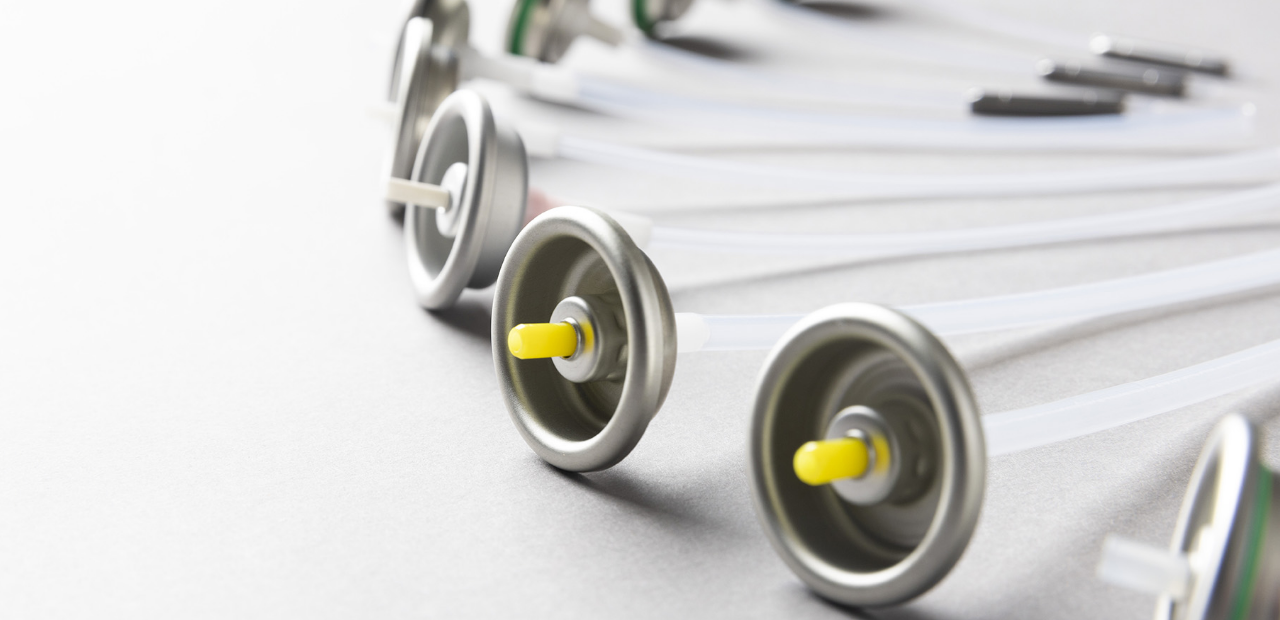

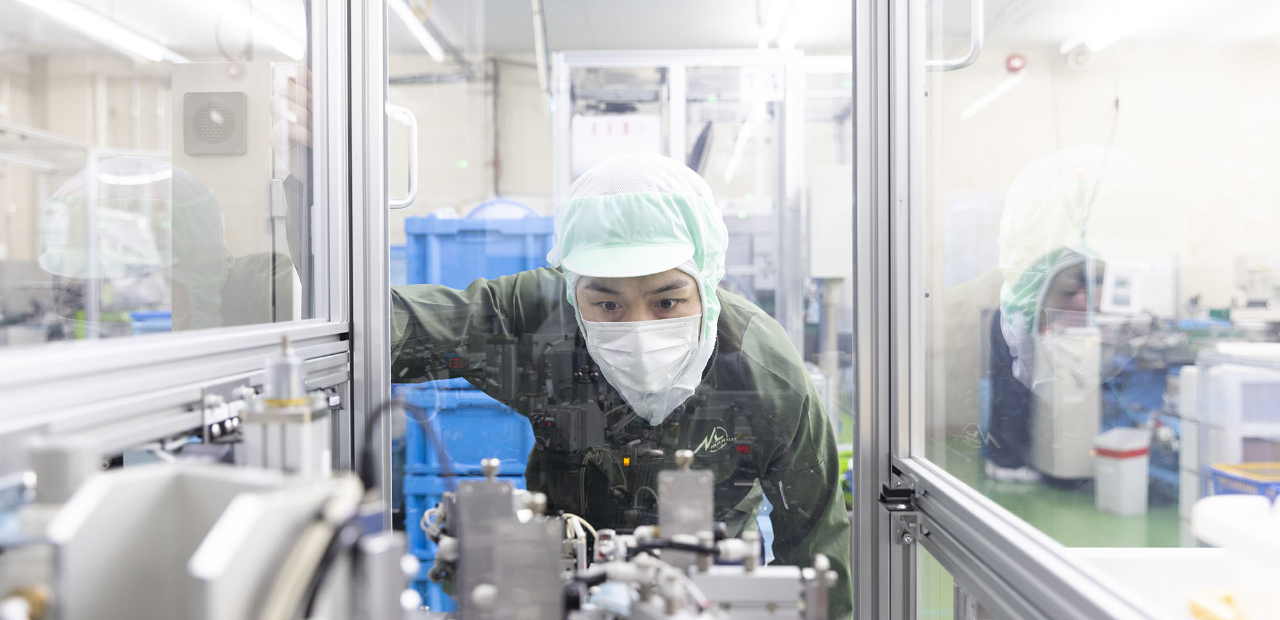

Strengths 丸一の強み

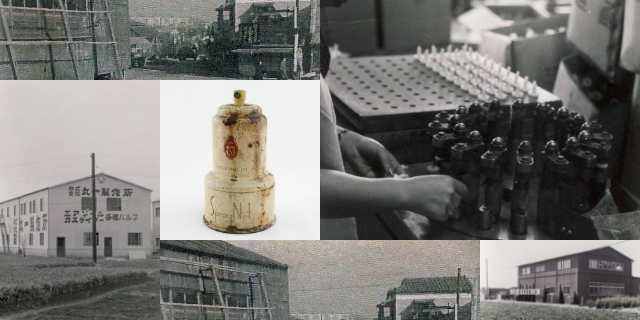

私ども丸一は1963年に株式会社丸一製作所を設立してから、エアゾールのパイオニアとして数多くの製品を生み続けてきました。

柔軟な発想を実現する商品企画、 最新鋭の技術、高品質管理、グローバルな視点での製品開発でお客様のニーズにスピーディに対応してまいります。

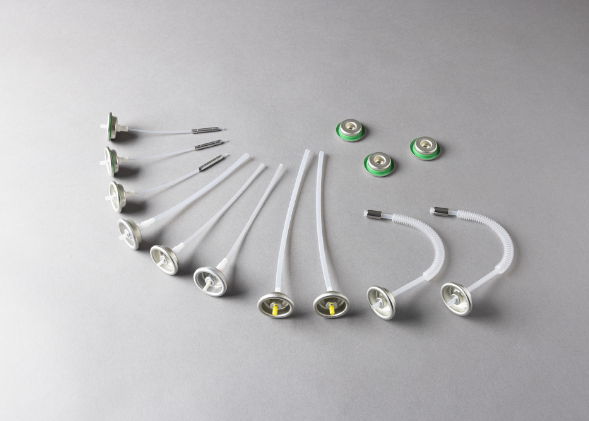

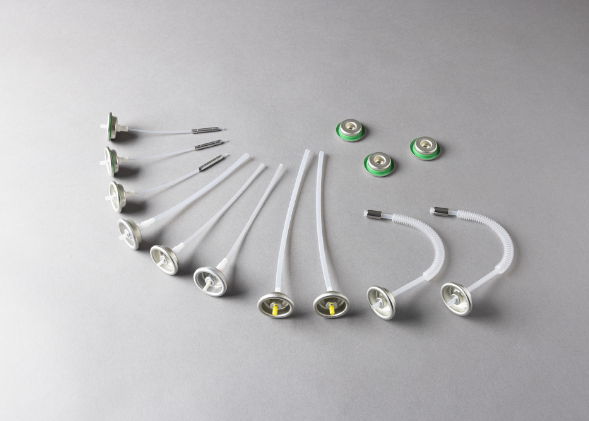

Products 製品情報

お客様のニーズに対し豊富な経験と明確な体制により、スピーディな商品開発を実現します。

私ども丸一は1963年に株式会社丸一製作所を設立してから、エアゾールのパイオニアとして数多くの製品を生み続けてきました。

柔軟な発想を実現する商品企画、 最新鋭の技術、高品質管理、グローバルな視点での製品開発でお客様のニーズにスピーディに対応してまいります。

お客様のニーズに対し豊富な経験と明確な体制により、スピーディな商品開発を実現します。